Finishing Types for Egyptian Marble Tiles and Slabs:

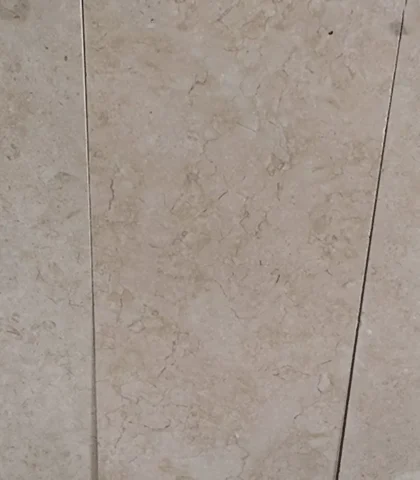

- Polished Finish: Polished finish is achieved by grinding the surface of the marble with a series of progressively finer abrasive tools. The marble surface becomes glossy and reflective due to this process, and it’s a popular choice for countertops and flooring.

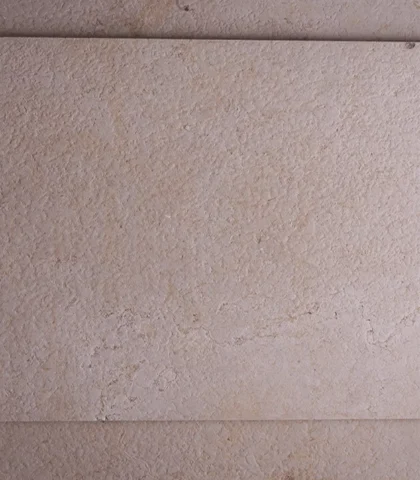

- Honed Finish: Honed finish is achieved by grinding the surface of the marble with a coarse abrasive tool that removes the uppermost layer of the stone. This gives the stone a matte appearance, which is great for high-traffic areas that are prone to scratches and wear.

- Brushed Finish: Brushed finish is achieved by brushing the surface of the marble with a wire brush, creating a textured surface that is natural and rustic. This finish is ideal for creating a country-style or old-world look.

- Acid Finish: Acid finish is achieved by applying an acid solution to the surface of the marble, which chemically reacts with the calcium carbonate in the stone and etches the surface. This process creates a slightly textured, matte surface.

- Sandblast Finish: Sandblast finish is achieved by blasting sand or other abrasive materials onto the surface of the marble, creating a rough, textured surface. This finish is often used for outdoor applications, such as paving stones and garden sculptures.

Egyptian Granite: Flamed finish is achieved by heating the surface of the granite with a flame torch until it starts to melt and flake. The surface is then brushed with a wire brush, removing the flaked material and leaving behind a rough, textured surface. This finish is ideal for outdoor applications, as it’s slip-resistant and can withstand extreme weather conditions.

Egyptian granite can be finished in a variety of ways, including polished, flamed, and sandblasted.

Polished finish involves grinding and polishing the granite surface to a high shine, resulting in a smooth and reflective surface. This finish is commonly used for interior and exterior applications, such as countertops, flooring, and walls.

Flamed finish, on the other hand, involves exposing the granite surface to intense heat, causing the crystals in the stone to burst and resulting in a rough, textured surface. This finish is commonly used for exterior applications, such as paving and landscaping.

Sandblasted finish involves using high-pressure air or water to blast sand or other abrasive materials onto the surface of the granite, resulting in a textured surface with a matte finish. This finish is commonly used for exterior applications, such as walls and cladding, as it provides excellent slip resistance.

In summary, polished granite finish is suitable for interior and exterior applications, flamed finish is suitable for exterior applications, and sandblasted finish is suitable for exterior applications that require slip resistance.

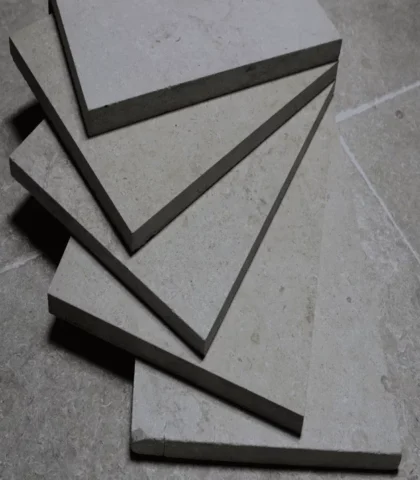

Limestone Flooring tiles

- Acid Finish: Acid finish is achieved by applying an acid solution to the surface of the limestone, which chemically reacts with the calcium carbonate in the stone and etches the surface. This process creates a slightly textured, matte surface.

- Brushed Finish: Brushed finish is achieved by brushing the surface of the limestone with a wire brush, creating a textured surface that is natural and rustic. This finish is ideal for creating a country-style or old-world look.

- Polished Finish: Polished finish is achieved by grinding the surface of the limestone with a series of progressively finer abrasive tools. The limestone surface becomes glossy and reflective due to this process, and it’s a popular choice for countertops and flooring.

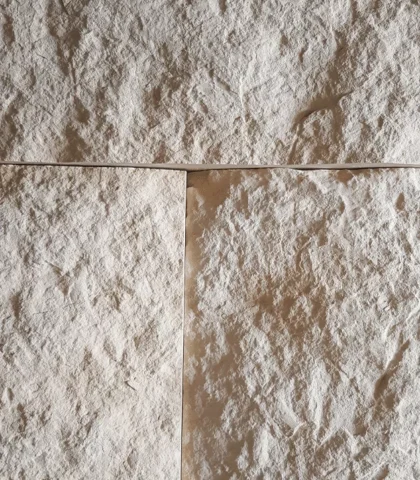

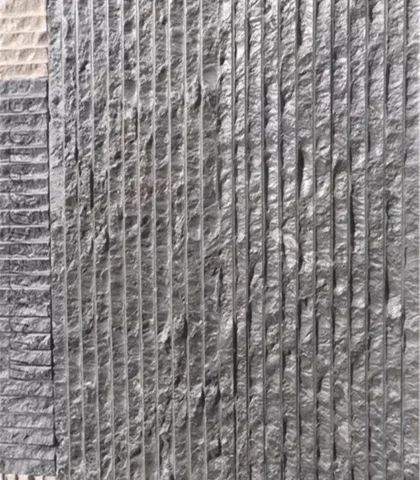

Split Face for Wall Cladding: Split face finish is achieved by splitting the stone along its natural bedding plane, creating a rough, textured surface. This finish is often used for wall cladding, creating an earthy and rustic look.

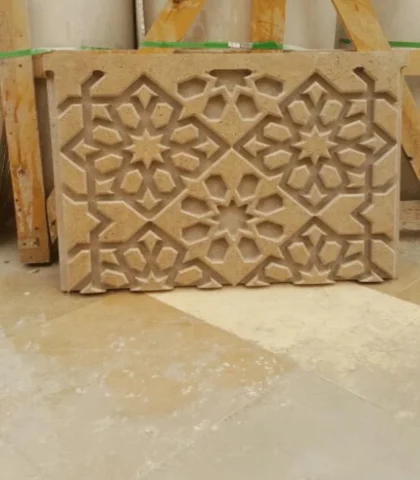

chiseled is a special type of finish that is unique to Egyptian marble. It’s achieved by hand-chiseling the surface of the marble to create a rough, textured surface that’s reminiscent of ancient Egyptian architecture. This finish is often used for decorative elements, such as columns and sculptures.

I hope this information helps you enhance your website content. Please let me know if you have any further questions or if there’s anything else I can help you with.

We offer a variety of finishing types for our Egyptian limestone paving, limestone tiles, marble tiles and slabs, and granite to cater to the specific needs of our clients. Here are some of the most common finishing types we provide:

Polished Finish: Our polishing machines use abrasives to grind the stone’s surface to create a smooth and reflective finish. It is best suited for indoor applications like flooring, walls, and countertops, but may not be recommended for areas with high foot traffic or outdoor use as it can become slippery when wet.

Honed Finish: Our honing machines use abrasives to grind the stone’s surface to create a matte finish. It is perfect for indoor applications like flooring, walls, and countertops, and can also be used for outdoor applications in areas that are not exposed to high foot traffic.

Tumbled Finish: Our tumbling machines use sand or small stones to create a textured and rustic surface. It is ideal for outdoor applications like patio paving, pool coping, and pool paving as it provides a slip-resistant surface.

Brushed Finish: Our brushing machines use a wire brush to create a textured surface that is not as rough as a tumbled finish. It is suitable for indoor and outdoor applications like flooring, walls, and countertops.

Sandblasted Finish: Our sandblasting machines use sand to create a textured and matte finish. It is perfect for outdoor applications like patio paving, pool coping, and pool paving as it provides a slip-resistant surface.

Flamed Finish: Our flaming machines expose the stone’s surface to high temperatures and rapidly cool it with water, creating a rough and textured surface. It is ideal for outdoor applications like patio paving, pool coping, and pool paving.

Leathered Finish: Our leathering machines use diamond-tipped brushes to create a textured and matte finish that provides a slip-resistant surface. It is suitable for indoor and outdoor applications like flooring, walls, and countertops.

In addition, we specialize in Egyptian marble, granite, and limestone floor finishing, catering to our clients’ specific requests for their respective applications. Keywords that may be relevant to our website include Marble in Egypt, Marble price, Granite in Egypt, Limestone in Egypt, Egyptian Marble types, Egyptian Marble suppliers, Manufacturing in Egypt, Marble companies in Egypt, Egyptian Tiles, Egyptian Marble prices, and Egypt manufacturing industry.